Prosthetics are artificial limbs or body parts that are designed to replace missing or non-functioning body parts. They play a crucial role in improving the quality of life for individuals with disabilities, allowing them to regain mobility and independence. However, traditional prosthetics can be expensive and often require lengthy and complex manufacturing processes. This is where 3D printed prosthetics come in.

Accessible 3D printed prosthetics have revolutionized the field of prosthetics by making them more affordable and customizable. With the advancements in 3D printing technology, it is now possible to create prosthetic limbs that are tailored to the specific needs and preferences of each individual. This has opened up new possibilities for people with disabilities, providing them with prosthetic solutions that are not only functional but also aesthetically pleasing.

Key Takeaways

- Accessible 3D printed prosthetics offer a promising future for people with disabilities.

- 3D printing technology allows for customization and cost-effectiveness in prosthetics.

- Materials used in 3D printed prosthetics provide strength, durability, and comfort.

- Innovative designs in 3D printed prosthetics improve functionality and aesthetics.

- Future advancements in materials and technology will continue to improve accessible prosthetics.

The Evolution of Prosthetics: From Traditional to 3D Printing

The history of prosthetics dates back thousands of years, with evidence of early prosthetic limbs found in ancient Egypt and Rome. These early prosthetics were made from materials such as wood, leather, and metal, and were often crude in design and function. Over the centuries, advancements in materials and technology led to the development of more sophisticated prosthetic devices.

Traditional prosthetics are typically made through a labor-intensive process that involves casting, molding, and shaping materials to create a custom fit for the individual. This process can be time-consuming and expensive, making it inaccessible for many people. In contrast, 3D printed prosthetics offer a faster and more cost-effective solution.

Advantages of 3D Printing in Prosthetics: Customization and Cost-Effectiveness

One of the key advantages of 3D printing in prosthetics is the ability to customize the design to fit the specific needs and preferences of each individual. With traditional prosthetics, adjustments and modifications often require additional time and cost. However, with 3D printing, changes can be made easily and quickly, allowing for a more personalized fit.

In addition to customization, 3D printed prosthetics are also more cost-effective compared to traditional prosthetics. The traditional manufacturing process involves multiple steps and requires skilled labor, which can drive up the cost. On the other hand, 3D printing eliminates many of these steps and reduces the need for manual labor, resulting in significant cost savings.

Materials Used in 3D Printed Prosthetics: Strength, Durability, and Comfort

| Materials Used in 3D Printed Prosthetics | Strength | Durability | Comfort |

|---|---|---|---|

| PLA | Low | Low | High |

| ABS | High | High | Low |

| PETG | High | High | High |

| Nylon | High | High | High |

| TPU | Low | Low | High |

A wide range of materials can be used in 3D printed prosthetics, each with its own unique properties and characteristics. Some of the commonly used materials include thermoplastics, carbon fiber composites, and titanium alloys. These materials are chosen for their strength, durability, and comfort.

Strength is an important factor in prosthetics as they need to withstand the forces exerted on them during daily activities. Durability is also crucial to ensure that the prosthetic can withstand wear and tear over time. Comfort is another key consideration as the prosthetic needs to be comfortable to wear for extended periods without causing discomfort or pain.

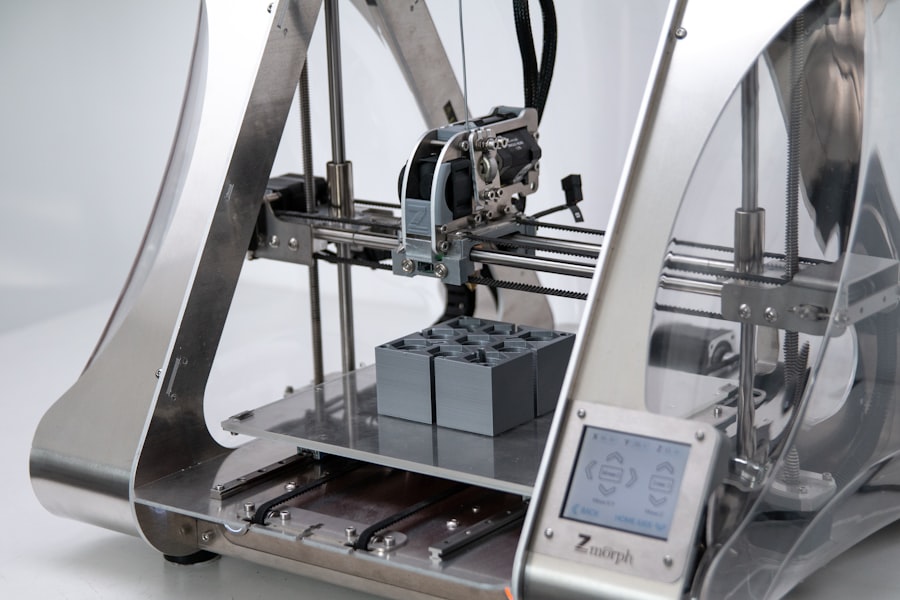

3D Printing Technology: How it Works and Its Impact on Prosthetics

3D printing, also known as additive manufacturing, is a process that involves building objects layer by layer using a digital model. The process begins with creating a 3D model of the prosthetic limb using computer-aided design (CAD) software. This digital model is then sliced into thin layers, which are sent to the 3D printer.

The 3D printer then builds the object layer by layer by depositing material in a precise pattern based on the digital model. This layer-by-layer approach allows for complex geometries and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods.

The impact of 3D printing on prosthetics has been significant. It has made prosthetics more accessible and affordable, allowing more people to benefit from these devices. It has also enabled the development of more customized and personalized prosthetics, improving the fit and function for individuals with disabilities.

Applications of 3D Printed Prosthetics: Hand, Arm, Leg, and Foot Prostheses

3D printed prosthetics have been used in a wide range of applications, including hand, arm, leg, and foot prostheses. Each type of prosthesis presents its own unique challenges and requirements, and 3D printing has allowed for innovative solutions to address these challenges.

For hand prostheses, 3D printing has enabled the development of functional and customizable designs that mimic the movement and dexterity of a natural hand. These prostheses can be controlled using muscle signals or other input methods, allowing individuals to perform a wide range of tasks.

Arm prostheses have also benefited from 3D printing technology. The lightweight and customizable nature of 3D printed prosthetics make them ideal for upper limb amputees who require a high level of functionality and comfort.

Leg and foot prostheses have also seen advancements with 3D printing. The ability to create custom-fit sockets and incorporate flexible materials has improved the comfort and fit of these prosthetics. Additionally, 3D printing has allowed for the development of dynamic foot designs that mimic the natural movement of a human foot.

Innovative Designs in 3D Printed Prosthetics: Improved Functionality and Aesthetics

One of the most exciting aspects of 3D printed prosthetics is the ability to create innovative designs that improve both functionality and aesthetics. Traditional prosthetics often have a utilitarian appearance, which can be a source of discomfort or self-consciousness for individuals.

With 3D printing, prosthetics can be designed to resemble natural body parts or incorporate artistic elements that reflect the individual’s personality. This not only improves the aesthetics but also boosts the individual’s self-confidence and acceptance of their prosthetic limb.

In terms of functionality, 3D printing has allowed for the development of prosthetics with improved range of motion, strength, and durability. The ability to create complex geometries and lightweight structures has resulted in prosthetics that are more efficient and comfortable to use.

Challenges and Limitations of 3D Printed Prosthetics: Regulatory and Ethical Issues

While 3D printed prosthetics offer many advantages, there are also challenges and limitations that need to be addressed. One of the main challenges is the lack of regulatory standards for 3D printed medical devices. Traditional prosthetics are subject to strict regulations to ensure safety and efficacy, but the same level of oversight does not yet exist for 3D printed prosthetics.

Ethical considerations also come into play when it comes to 3D printed prosthetics. For example, there are concerns about the potential for individuals to create and distribute prosthetics without proper training or expertise. This raises questions about the quality and safety of these devices.

Another limitation is the availability of materials suitable for 3D printing prosthetics. While there are a variety of materials available, not all are suitable for medical applications. More research and development is needed to identify and optimize materials that meet the specific requirements of prosthetics.

Future Directions in 3D Printed Prosthetics: Advancements in Materials and Technology

The future of 3D printed prosthetics looks promising, with ongoing advancements in materials and technology. Researchers are exploring new materials that offer improved strength, durability, and comfort. They are also investigating new manufacturing techniques that can further enhance the capabilities of 3D printed prosthetics.

One area of focus is bio-printing, which involves using living cells to create functional tissues and organs. While this technology is still in its early stages, it has the potential to revolutionize the field of prosthetics by allowing for the creation of fully functional and biocompatible prosthetic limbs.

Advancements in 3D scanning technology are also expected to play a role in the future of 3D printed prosthetics. The ability to capture accurate and detailed measurements of the individual’s residual limb will further improve the fit and comfort of prosthetic devices.

The Promising Future of Accessible 3D Printed Prosthetics for People with Disabilities

In conclusion, accessible 3D printed prosthetics have transformed the field of prosthetics by making them more affordable, customizable, and aesthetically pleasing. The ability to create personalized prosthetic limbs that meet the specific needs and preferences of each individual has opened up new possibilities for people with disabilities.

While there are challenges and limitations that need to be addressed, the future of 3D printed prosthetics looks promising. Ongoing advancements in materials and technology, along with the development of regulatory standards, will further improve the safety, efficacy, and accessibility of these devices.

With continued research and innovation, 3D printed prosthetics have the potential to revolutionize the lives of individuals with disabilities, providing them with functional and comfortable solutions that enhance their mobility and independence.

If you’re interested in learning more about the website terms and conditions of use, Tablet Jankari has a comprehensive article that covers all the important aspects. It’s crucial to understand these terms before engaging with any online platform. Additionally, if you want to know more about Tablet Jankari and its mission, their “About Us” page provides detailed information about the team behind the website. Lastly, if you’re curious about the background and history of Tablet Jankari, their “About” page offers insights into their journey. Check out these links for a deeper understanding of Tablet Jankari and its offerings.

FAQs

What are customizable 3D printed prosthetics?

Customizable 3D printed prosthetics are artificial limbs that are created using 3D printing technology. They are designed to fit the specific needs and requirements of the individual user.

How do 3D printed prosthetics differ from traditional prosthetics?

3D printed prosthetics are typically less expensive and more customizable than traditional prosthetics. They can also be produced more quickly and with greater precision.

Why are customizable 3D printed prosthetics becoming more accessible?

Advancements in 3D printing technology have made it easier and more affordable to produce customizable prosthetics. Additionally, there is a growing demand for prosthetics that are tailored to the individual needs of the user.

Who can benefit from customizable 3D printed prosthetics?

Customizable 3D printed prosthetics can benefit anyone who requires an artificial limb, including individuals who have lost a limb due to injury, illness, or congenital conditions.

What are some of the advantages of using customizable 3D printed prosthetics?

Customizable 3D printed prosthetics offer a number of advantages, including greater comfort, improved functionality, and a more natural appearance. They can also be produced more quickly and at a lower cost than traditional prosthetics.